2025/01/28

Years pass quickly. In 2018, we published the results of a comparison between an early Solbian module (named CP220) and three commercially available glass modules from well-known brands. The Solbian module was based on monocrystalline cells with two busbars (truly another era) and a polymeric sandwich that has been continuously improved since then.

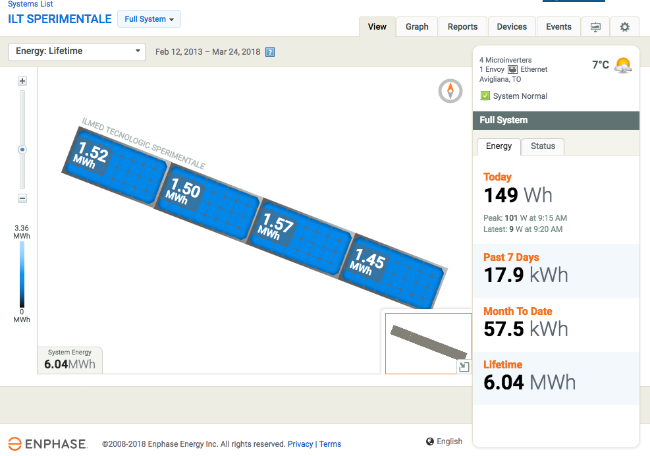

The results of the five-year comparison can be found here, with all the details of the system. The CP220 performed remarkably well; in fact, among the four modules examined, it exhibited the lowest relative degradation.

Since then, we had almost forgotten about this product, but the monitoring continued, albeit with some technical blackouts.

Now, after another five years of testing, we summarize what has happened in the meantime, starting immediately with the graphs.

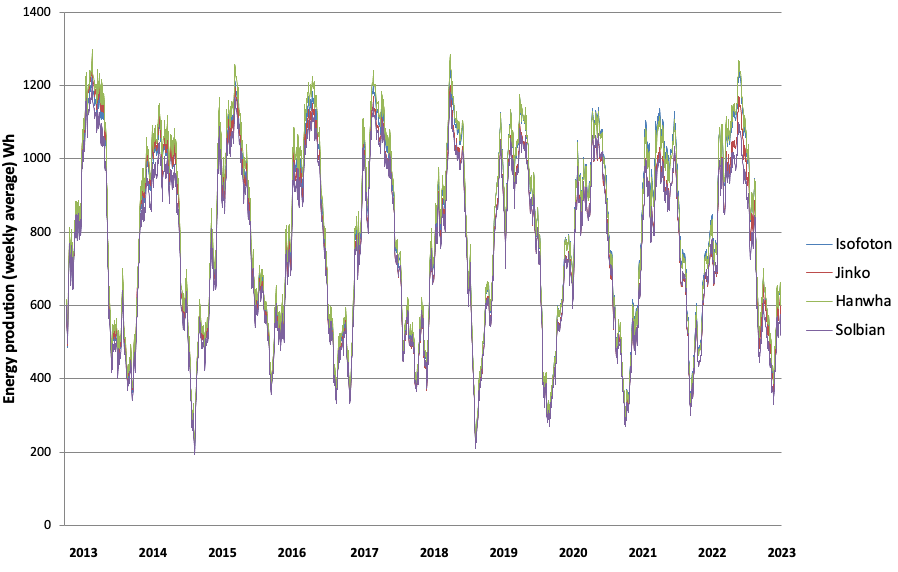

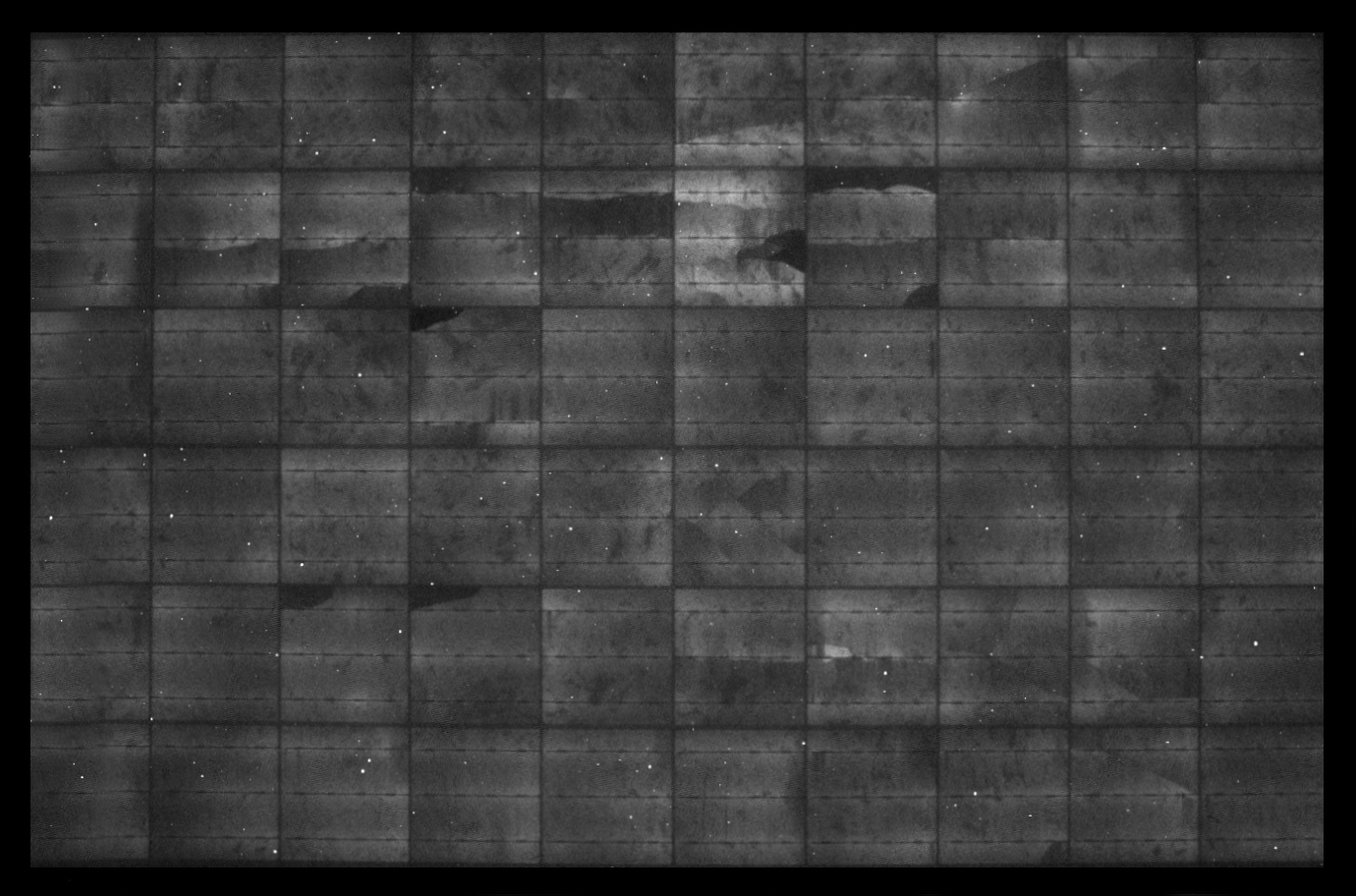

An overview of the entire operational period:

Even over a ten-year period, the general trend in energy production is fairly consistent among the four modules, although in the final phase, the various curves tend to diverge.

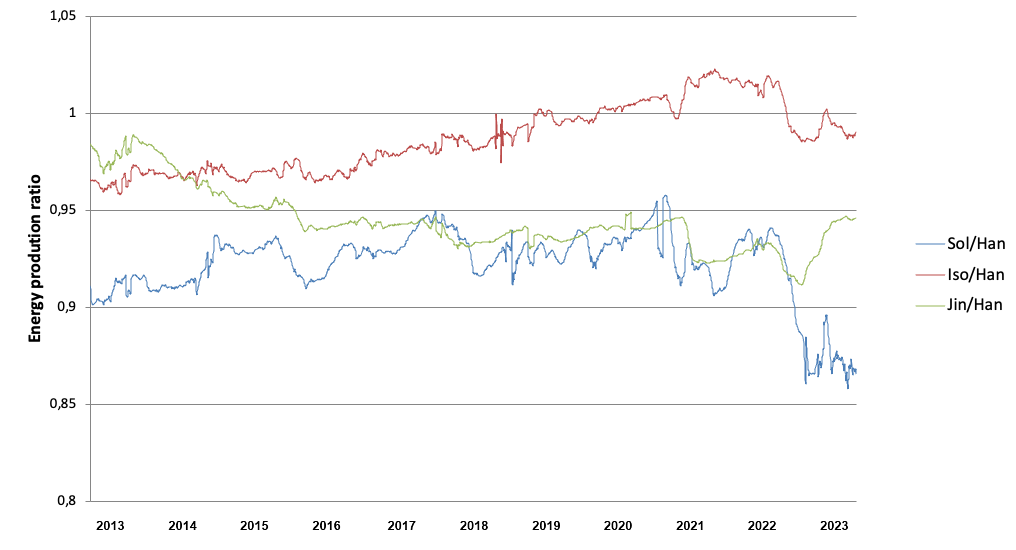

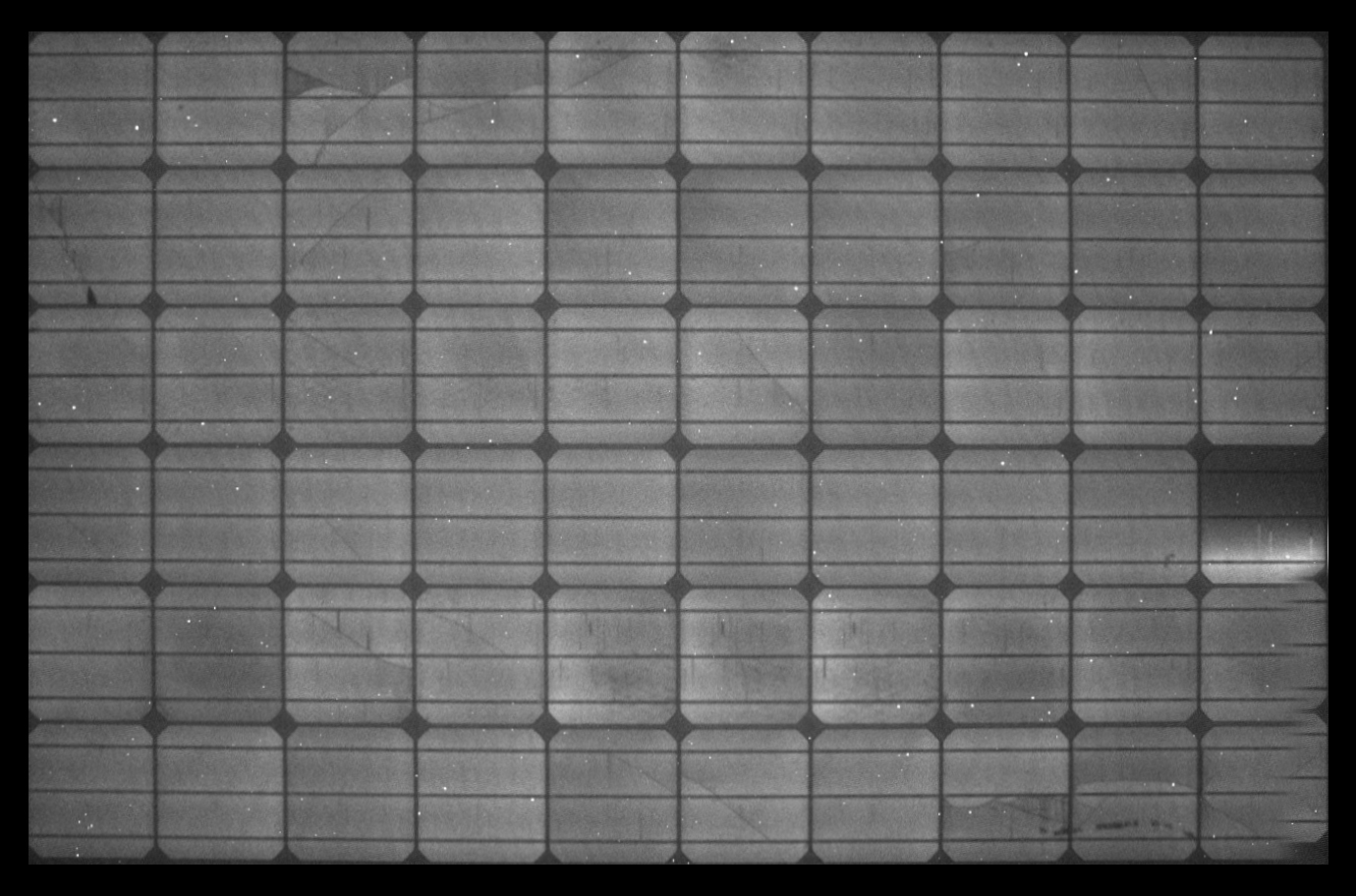

We now proceed with the comparative analysis, as done in the first report, by comparing the three modules with the one that had previously shown the best performance, Hanwha. Here are the results:

Until mid-2000, everything continued along the lines of previous years, with the Isofton module consistent relative reprise in comparison to Hanwha, and the Solbian module maintaining its relative performance, having matched Jinko’s productivity by the fifth year, despite Jinko having a 10% higher nominal power at the start.

Two events significantly altered the scenario: one in autumn 2020 and another in mid-2022. All curves show strong relative variations, both decreases and increases. This may seem odd, but remember that the curves represent the ratio of energy produced by the modules compared to the Hanwha reference. Thus, a decrease in Hanwha’s productivity results in an increase in the relative ratio. However, it is clear that something happened, particularly in mid-2022, when a significant drop in power occurred, especially for the Solbian module, but also for Isofoton. We decided to investigate, recalling a major weather event: a severe hailstorm.

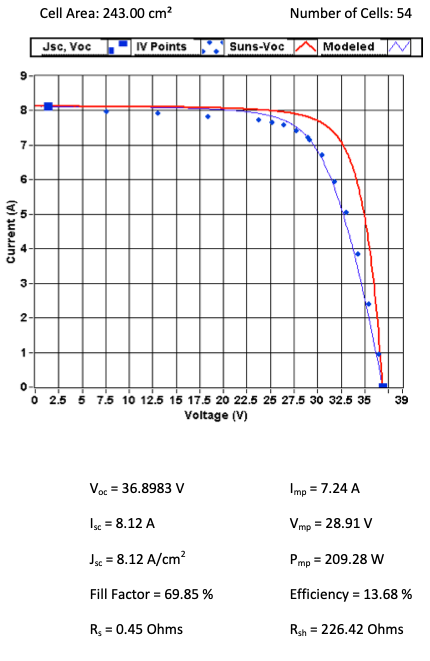

We dismantled the four modules and brought them to our facility to measure their power with a solar simulator and observe them under electroluminescence.

The result was very clear: after a decade, hail had taken its toll on a polymeric module.

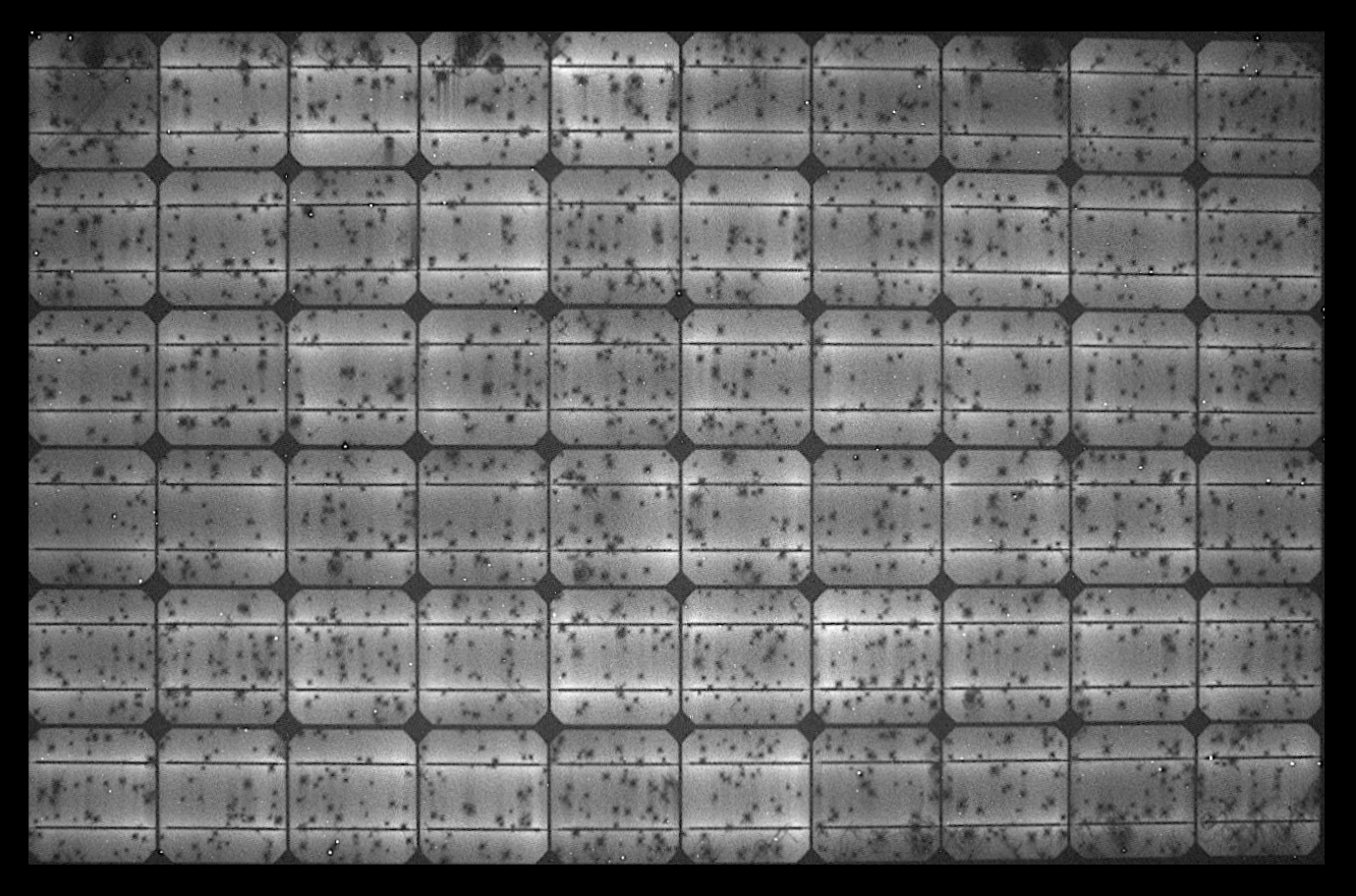

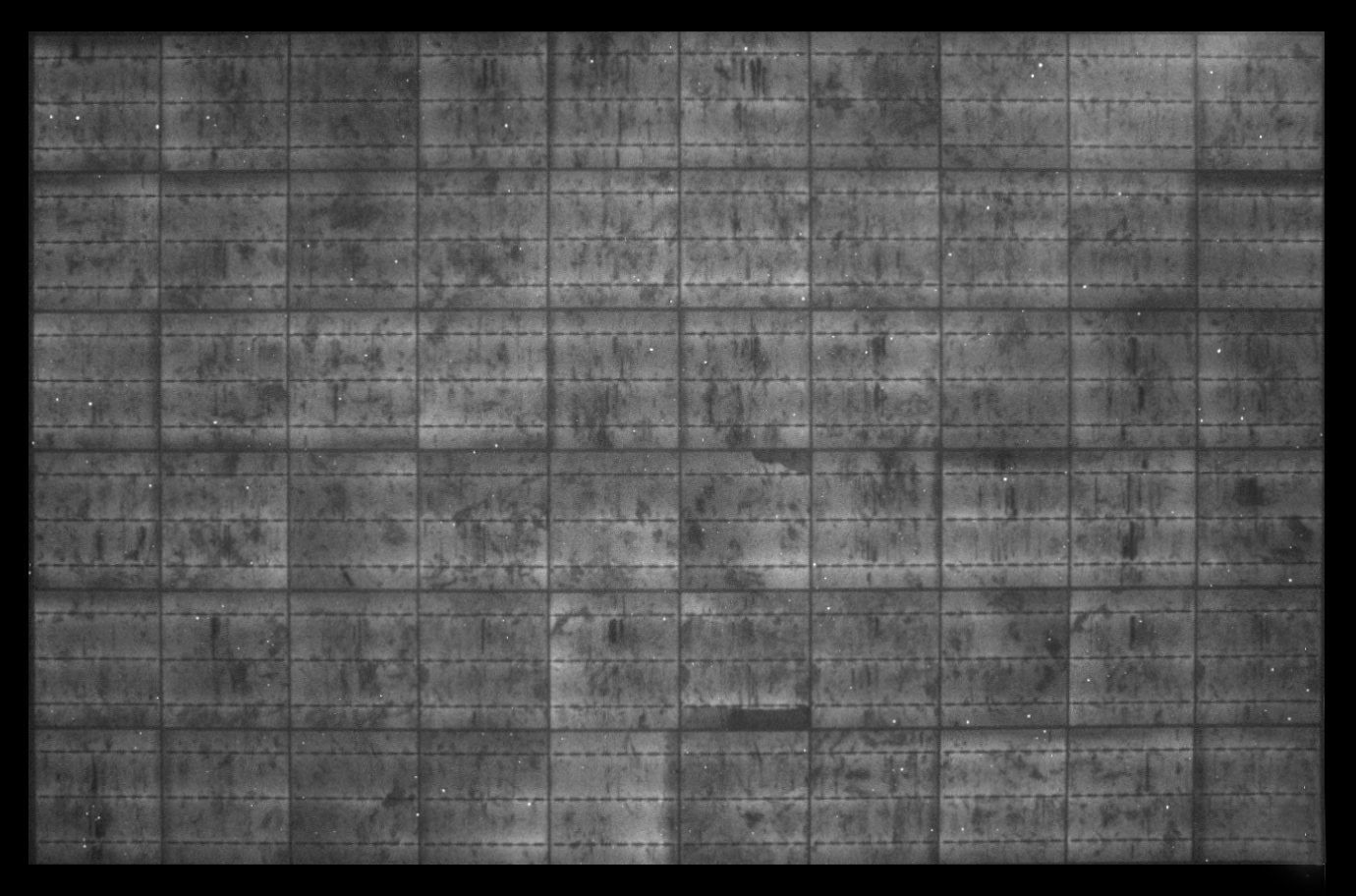

Here is the electroluminescence image of the Solbian module:

Despite undeniable hail damage, the module continued to function. There were no dead zones, and the individual cells, though dented, still produced energy. This was confirmed by solar simulation, which indicated a maximum power output just below 210 W, a 5% degradation. After ten years and a hailstorm like that, this is well within the warranty limits of the time! The other modules also suffered some damage, as shown by the production graphs, but to a lesser extent. The key difference between a polymeric module and a glass-and-aluminum one is impact resistance.

In recent years, Solbian has worked extensively on this aspect, selecting more resistant polymeric materials and different layering structures that better absorb impacts, minimizing damage to cells. Additionally, we have opted for inherently resilient solar cells that mitigate the effects of minor damage, such as hail impacts. We have abandoned busbar cell technology in favor of multi-busbar technology. Among these, Maxeon cells, used in our SP series, represent the best market solution due to a dense network of metallic contacts on the cell's back (back-contact technology). This feature allows Maxeon cells to maintain productivity even if severely damaged, and most importantly, prevents damage from worsening over time.

A different technology is used in the SR series, featuring a patented design by the US-based company Merlin Solar. These are not back-contact cells, but thanks to a rear metal grid and an engineered front contact mask, they also exhibit high resilience.

To support this strategy, Solbian is conducting tests based on photovoltaic hail standards to simulate and study the impact of such events on flexible polymeric panels, aiming to surpass current IEC 61215 and IEC 61730 standards.

Our CP220, born when Solbian was still in its infancy, did not incorporate all these innovations, but it has admirably withstood over ten years of operation and adverse weather conditions.

However, we know what will happen in the future, and in fact, it is already happening. The microcracks produced by the hail, under the action of thermal fluctuations, will tend to widen, and the cell, not held together by the metallic structures that characterize Maxeon or Merlin Solar cells, will quickly lose efficiency.

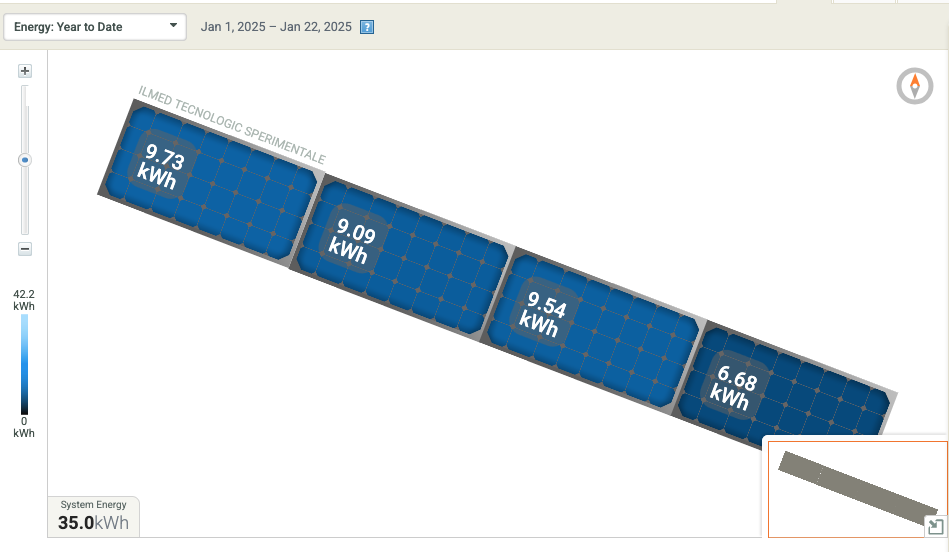

As of today, one year after the modules were reinstalled on the roof to continue the test, the productivity of the Solbian module is at 71% compared to the average of the other three modules (it started at 90% due to lower power), but its efficiency is gradually declining. A long farewell for a module that has taught us so much.

Solbian EA Srl

January 2025